Breaking of Wire

When the wire is loaded beyond the elastic limit, then strain increases much more rapidly. The maximum stress corresponding to B (see stress-strain curve) after which the wire begin to flow and breaks, is called breaking stress or tensile strength and the force by application of which the wire breaks is called the breaking force.

(i) Breaking force depends upon the area of cross-section of the wire i.e., Breaking force µ A

\ Breaking force = P × A

Here P is a constant of proportionality and known as breaking stress.

(ii) Breaking stress is a constant for a given material and it does not depends upon the dimension (length or thickness) of wire.

(iii) If a wire of length L is cut into two or more parts, then again it's each part can hold the same weight. Since breaking force is independent of the length of wire.

(iv) If a wire can bear maximum force F, then wire of same material but double thickness can bear maximum force 4F because Breaking force pr2.

(v) The working stress is always kept lower than that of a breaking stress.

So that safety factor = may have large value.

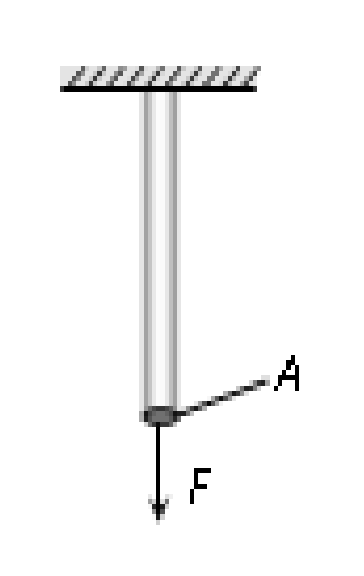

(vi) Breaking of wire under its own weight.

Breaking force = Breaking stress ´ Area of cross section

Weight of wire = Mg = ALdg = PA [As mass = volume ´ density = ALd]

This is the length of wire if it breaks by its own weight.

SureDen

SureDen